Post Treatment Catalyzed Particulate Filter DPF System OEM ODM

Honeycomb ceramic substrates are used in industrial waste gas purification systems. Industrial carriers are coated with catalysts and are widely used in voCs waste gas purification, industrial waste gas treatment heat exchange systems, NOx purification systems, flue gas denitrification in thermal power plants, and purification of harmful gases from waste incineration.

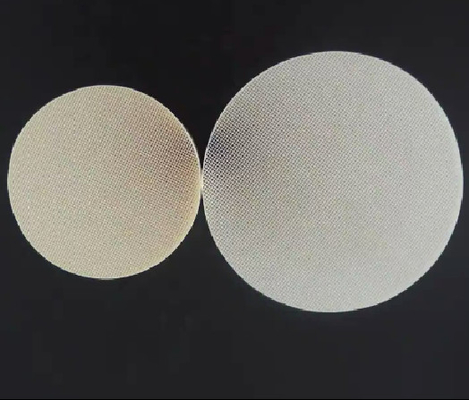

Diesel Particulate Filter (DPF)

Diesel particulate filters are mainly used in diesel exhaust gas purification systems to solve air pollution problems.

It adopts a honeycomb structure with independent openings and blocked channels at both ends. Exhaust gas enters through one open end, then passes through the porous honeycomb wall, and finally exits through adjacent channels. Carbon particles are left on the channel walls because they are too large to pass through the wall pores and are not released into the air.

Diesel particulate filter can effectively remove black smoke (PM, such as hydrocarbons, soot) in the exhaust of diesel engines, and usually DPF can remove 90% or more of soot.

Catalytic Diesel Engine Particulate Filter cDPF Features:

1. High PM filtration efficiency (>90%);

2. PN high filtration efficiency (>95%);

3. The passive regeneration temperature is low, and the equilibrium temperature is lower than 320 ° C.

4. High active regeneration efficiency. When the temperature is higher than 550°C, the active regeneration efficiency is over 90%, and the regeneration time is within 10 minutes.

5. Highly stable coating.

6. Low back pressure.

7. Emission standards comply with Euro V, Euro VI, BS V, BS VI.

8. We can develop different catalyzed diesel particulate filters according to customer's requirements.

About Sinocat

Sinocat Environmental Technology Co., Ltd. (Stock Code: 688737), founded in 2005, is listed on the science and Innovation Board of Shanghai Stock Exchange. The company is committed to the research and development of new materials and new energy technologies such as natural gas (CNG / LNG), diesel, gasoline and other fuel engine emission post-treatment catalysts (converters) and hydrogen fuel cell catalysts. The company is a key high-tech enterprise of the national Torch Plan technology, R&D, manufacture, sales and service.

Buildings & Facilities

![]()

Workshops & Equipment

![]()

Series of Products

![]()

Certificates

Sinocat attached high importance to our system building and is an IATF, ISO and other well-known international organizations certified company.

Packing & Shipment

![]()