Aluminum Alloy VOC Oxidation Catalyst 200 300 CPSI For VOC And SCR Treatment

-

High Light

Aluminum Alloy VOC Oxidation Catalyst

,200 CPSI VOC Oxidation Catalyst

,Square Voc Removal Catalyst

-

ApplicationFactory VOCs Treatment\ Industrial Ceramic

-

Substrate MaterialAluminum Alloy And Others

-

Coating MaterialPrecious Metal, Rare Earth Element

-

Hole ShapeSquare, Hexagon Circular And So On

-

UsageRTO, HTAC, RCO, VOC And SCR Treatment.

-

Cell Density200 - 300 CPSI

-

Place of OriginChina

-

Brand NameSinocat

-

CertificationISO9001

-

Model NumberVOCs

-

Minimum Order Quantity1 Set

-

PriceAs per technical requirements.

-

Packaging DetailsAs per requirement.

-

Delivery Time45 days

-

Supply Ability200 sets per month.

Aluminum Alloy VOC Oxidation Catalyst 200 300 CPSI For VOC And SCR Treatment

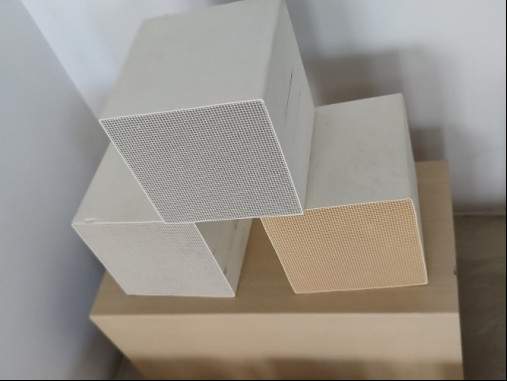

ZVPD Cubic VOC Oxidation Catalyst 200 300 CPSI Voc Removal Catalyst

ZVPD-type organic exhaust gas purification catalyst takes modified alumina of high temperature and high specific surface area, rare earth oxygen storage material of high performance, and perovskite-type transition oxide as catalytic material carrier, it takes precious metal platinum (PT) and palladium (PD) as main active components. By matching catalytic materials and active species of precious metal perfectly, and dispersing them into the catalytic materials evenly, the catalyst with low ignition temperature and high durability is formed. It is a low temperature and high efficiency industrial exhaust gas purification catalyst with independent patent right.

Honeycomb ceramic regenerator is the key and core component of regenerative high temperature combustion technology (HTAC technology). Regenerative high-temperature combustion technology (HTAC technology) is a new concept of combustion technology, which organically combines waste heat recovery of flue gas with high-efficiency combustion and reduction of NOx emissions, and achieves the dual purpose of energy saving and limiting NOx emissions.

Honeycomb ceramics for heat exchange include ceramic honeycomb heat recovery beds, heat exchange beds, heat storage and recovery ceramic media, and heat exchange elements/media. Ceramic monolithic media provide significant energy savings in iron and steel plants, the metallurgical industry, and in regenerative thermal oxidizers (RTO). The honeycomb integral furnace is the key component of the furnace, which is widely used in various heaters, sirocco furnaces, heat treatment furnaces, pyrolysis towers, roasting furnaces, melting furnaces, and balance heating furnaces. This technology can save more than 40-70% of energy.

Application:

The catalyst is suitable for purifying industrial VOCs exhaust gas containing ozone (O3), carbon monoxide (CO), hydrocarbon (CxHy), benzene and its derivatives, olefins and its derivatives and aldehydes.

Features:

1. High purification efficiency.

When the concentration of hydrocarbon organic matter is in the range of 300~8000mg/m3, the air velocity is 5000-15000 h-1 and the inlet temperature of reaction gas is 300~550°C, the purification efficiency is more than 99%, which is thorough without secondary pollution.

Performance Comparison (Red & Purple: Sinocat Designs)

![]()

2. Good Thermal Stability.

The catalyst can withstand instantaneous thermal shock of high temperature of 600°C.

3. Long Service Life

The catalyst has a service life more than two years. Specific service life can be customized according to the user’s requirements.

4. Strong Anti-poisoning Performance.

It can tolerate a certain concentration of S, Pb, As and other compounds.

5. Wide Range of Application.

ZVMC can be used in chemical, printing, food, machinery, instrumentation, manufacturing, coating, petrochemical, pharmaceutical and many other industries.

Product specifications:

| Dimensions | 100mm*100mm*50mm | 150mm*150mm*150mm |

| Cell Density | 200 cells/in2 ;300 cells/in2 | 200 cells/in2 ;300 cells/in2 |

| Type | Honeycomb coating | |

| Airspeed Range | 5000-30000h-1 | |

| Remarks | 1. Cross-section dimension:100*100,150*150. | |

| 2. Carrier height:50mm~400mm | ||

| 3. Number of cells:35 cells/in2~400 cells/in2 | ||

| 4. Can be designed on the specific requirement of each customer | ||

Customer Service:

Our company can provide customized solutions according to the type and concentration of gas.