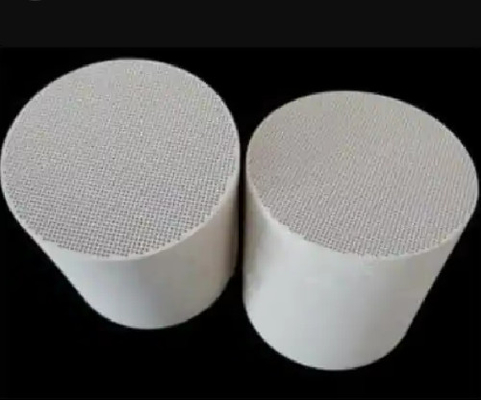

EURO VI Generator Catalytic Converter Selective Catalytic Reduction Filter SCRF

1. SCR technology refers to the use of a denitrification catalyst at a certain temperature (270-400 degrees), and after nitrogen and water have a selective catalytic reduction reaction, the NOX in the flue gas is mixed with the ammonia in the reducing agent and supplied to the system. Thereby reducing NOX emissions and reducing the pollution of flue gas to the environment.

2. At present, commercial SCR catalysts mainly use TiO2 as the substrate, V2O5 as the main active component in WO3, and MoO3 as an auxiliary component for anti-oxidation and anti-drug.

3. Characteristics of high performance honeycomb SCR catalyst

a: high activity and NOx removal efficiency

b: SO2 conversion rate is low

c: Low NH3 leakage

d: Excellent positioning and wear resistance

e: high durability and stability

f: Small size, high specific surface area, economical and practical.

Major reactions are:

| 4NH3+4NO+O2→4N2+6H2O |

| 2NH3+NO+NO2→2N2+3H2O |

| 8NH3+6NO2→7N2+12H2O |

Performance (Conversion Efficiency):

![]()

Meet on-road diesel engine National VI, Euro VI, and non-road T4 standards.

About Sinocat

Sinocat Environmental Technology Co., Ltd. (Stock Code: 688737), founded in 2005, is listed on the science and Innovation Board of Shanghai Stock Exchange. The company is committed to the research and development of new materials and new energy technologies such as natural gas (CNG / LNG), diesel, gasoline and other fuel engine emission post-treatment catalysts (converters) and hydrogen fuel cell catalysts. The company is a key high-tech enterprise of the national Torch Plan technology, R&D, manufacture, sales and service.

![]()

The Main Entrance

![]()

The Office Building

![]()

Robots in the Factory

![]()

Robots in the Facotry

![]()

View of Workshop

![]()

View of Work Shop

![]()

![]()

![]()

![]()

Inspection

Certificates

Sinocat attached high importance to our system building and is an IATF, ISO and other well-known international organizations certified company.

![]()

![]()

![]()

![]()

Packing & Shipment

![]()

![]()

![]()