-

High Light

Petrochemical Emission VOC Oxidation Catalyst

,voc catalytic oxidation 600 CPSI

,Square VOC Oxidation Catalyst

-

FeaturesHigh Efficiency Up To 98%

-

ApplicationPetroChemical, Pharmaceutical, Printing

-

MaterialActivated Carbon

-

ShapeSquare \Round

-

AdvantagesLow Energy Consumption

-

Place of OriginChina

-

Brand NameSinocat

-

CertificationISO9001

-

Model NumberVOCs

-

Minimum Order Quantity1 Set

-

PriceAs per technical requirements.

-

Packaging DetailsAs per requirement.

-

Delivery Time45 days

-

Payment TermsL/C, T/T

-

Supply Ability200 sets per month.

Petrochemical Emission VOC Oxidation Catalyst 600 CPSI Square

VOC Catalyst (Industrial & Stationary & Petro-chemical Emission Catalyst)

Stationary Petrochemical Emission VOC Oxidation Catalyst 600 CPSI

VOCs Catalysts

Volatile organic compounds (VOCs) are one of the environmental pollutants. There are many types of VOCs. Outdoor VOCs mainly come from chemical production and automobile exhaust emissions, and indoor ones are mainly from construction and decoration materials. While VOCs are released into the air, they will destroy the ozone layer and produce photochemical smog, and cause great harm to human health. At present, the main treatment processes are adsorption, thermal incineration, plasma, photocatalysis and catalytic oxidation, etc. Besides, treatment methods of multi-process combinations have been applied.

While there are many methods to abate VOC emissions, catalytic incineration has become one of the most famous choices because it can be more versatile and economical than other approaches. Sinocat has been developing highly active and robust catalysts and related technologies for the reduction of volatile organic compounds (VOCs). Sinocat catalysts control emissions of hydrocarbons (HCs) and other VOCs from a wide variety of industrial processes. They help customers meet increasingly stringent emissions standards reliably and cost-effectively.

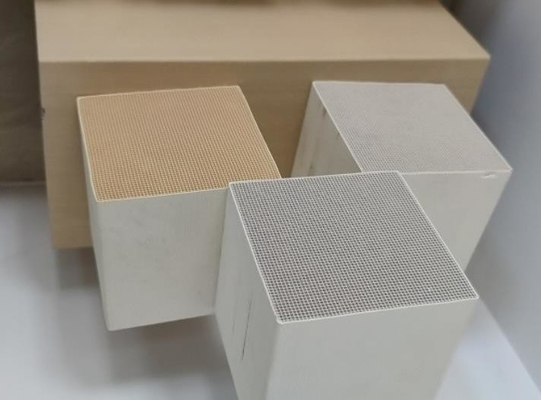

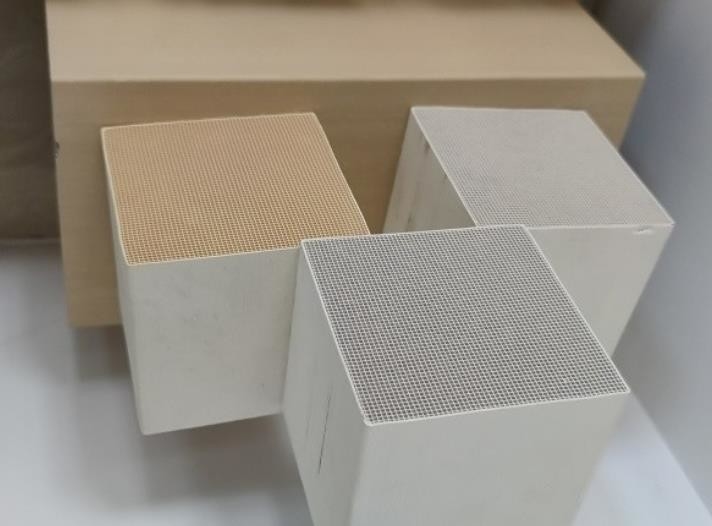

VOC Catalyst Substrate

| No. | Type of Substrate | Image | Features |

| 1 | Square cordierite honeycomb ceramic substarte |

|

|

| 2 | Square metal honeycomb substrate |

|

|

| 3 | Cylindrical cordierite honeycomb substrate |

|

Technical Features

1. With very high efficiency up to 98%.

2. No secondary pollution.

3. Low energy consumption due to low VOCs ignition temperature and high thermal energy recovery.

4. Very low operation and maintenance cost.

About Sinocat

Sinocat Environmental Technology Co., Ltd. (Stock Code: 688737), founded in 2005, is listed on the science and Innovation Board of Shanghai Stock Exchange. The company is committed to the research and development of new materials and new energy technologies such as natural gas (CNG / LNG), diesel, gasoline and other fuel engine emission post-treatment catalysts (converters) and hydrogen fuel cell catalysts. The company is a key high-tech enterprise of the national Torch Plan technology, R&D, manufacture, sales and service.

![]()

The Main Entrance

![]()

The Office Building

![]()

Robots in the Factory

![]()

Robots in the Facotry

![]()

View of Workshop

![]()

View of Work Shop

![]()

![]()

![]()

![]()

Inspection

Certificates

Sinocat attached high importance to our system building and is an IATF, ISO and other well-known international organizations certified company.

![]()

![]()

![]()

![]()

Packing & Shipment

![]()

![]()

![]()